capabilities

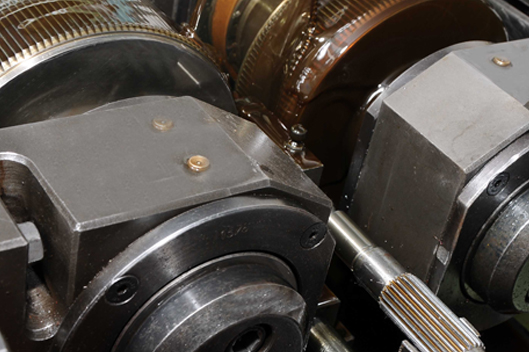

Since its establishment in 1996, Globe Components Pvt. Ltd. has grown to encompass over 70,000 sq. ft. of manufacturing facilities strategically placed across seven locations in Ambattur, Chennai. Our comprehensive machining capabilities include Profile and Generation Gear Grinding, CNC Turning, CNC Cylindrical Grinding, VMC up to 5 Axis, Rack Rolling, Broaching, Circular Saw Cutting, Gun Drilling, Centerless and Cylindrical Grinding, along with a variety of Special Purpose Machines for milling and drilling.

Our team consists of more than 29 experienced engineers and an additional 80 engineers, supported by a skilled workforce of 500. We are IATF-16949 certified, ensuring adherence to the highest quality standards. Our fully equipped standards room features CMM, contour testing equipment, surface roughness testers, 2D profile testing capabilities, and zero-grade gauge blocks.

ongoing projects

In our ongoing pursuit of excellence, we are enhancing our manufacturing capabilities while also launching our own forging and precision gear cutting facilities, which will feature Profile and Generation Gear Grinding. This initiative is intended to strengthen our position as a comprehensive solutions provider and a reliable partner for OEMs and Tier-1 companies in industrial applications, overseas markets, and the automotive and EV sectors.

the global advantage

- 29+ years manufacturing experience

- Supplying OEM / Tier-I across Two-wheeler, Cars, Commercial vehicles and Tractor segments

- In-house source for cold-drawn, peeled and ground alloy steel

- In-house facility for heat treatment (SQF) and precision gear cutting (in-progress)